punker fan production in Europe, Germany, the production base has 70 years of production history, with highly sophisticated production equipment and perfect process, for punker fan to create a leading domestic technology of high-quality energy-saving fan provides a rigorous quality assurance. Our company, as the sales company of punker fan in China, is committed to introducing these high quality fan products into the Chinese market and providing professional solutions for our customers.

We are a fan supplier with independent design, production and brand, we provide professional and efficient impellers, fans and professional energy saving solutions for air system. The company's main brand is punker fan, which covers EC fan, Plug fan, explosion-proof fan and other fans, widely used in commercial buildings, industrial plants and other fields. The company provides German punker products and energy-saving ventilation solutions, its fans are produced in Germany, with 70 years of production history, excellent equipment, perfect process, "energy saving and environmental protection" as the concept, "quality first" as the principle, to provide customized solutions, products and high quality service for customers. We provide customized solutions, products and high quality services to our customers with the concept of "energy saving and environmental protection" and "quality first".

PANKA fan production in Europe, Germany, the production base has 70 years of production history, with highly sophisticated production equipment and perfect process, for PANKA fan to create a leading technology in the domestic high-quality energy-saving fan provides a rigorous quality assurance.

With the product concept of "energy saving and environmental protection" and the principle of "quality first", PANKA Fans is applied in different fields to provide tailor-made solutions, products and high quality services for customers with different needs.

May Punch be with you!

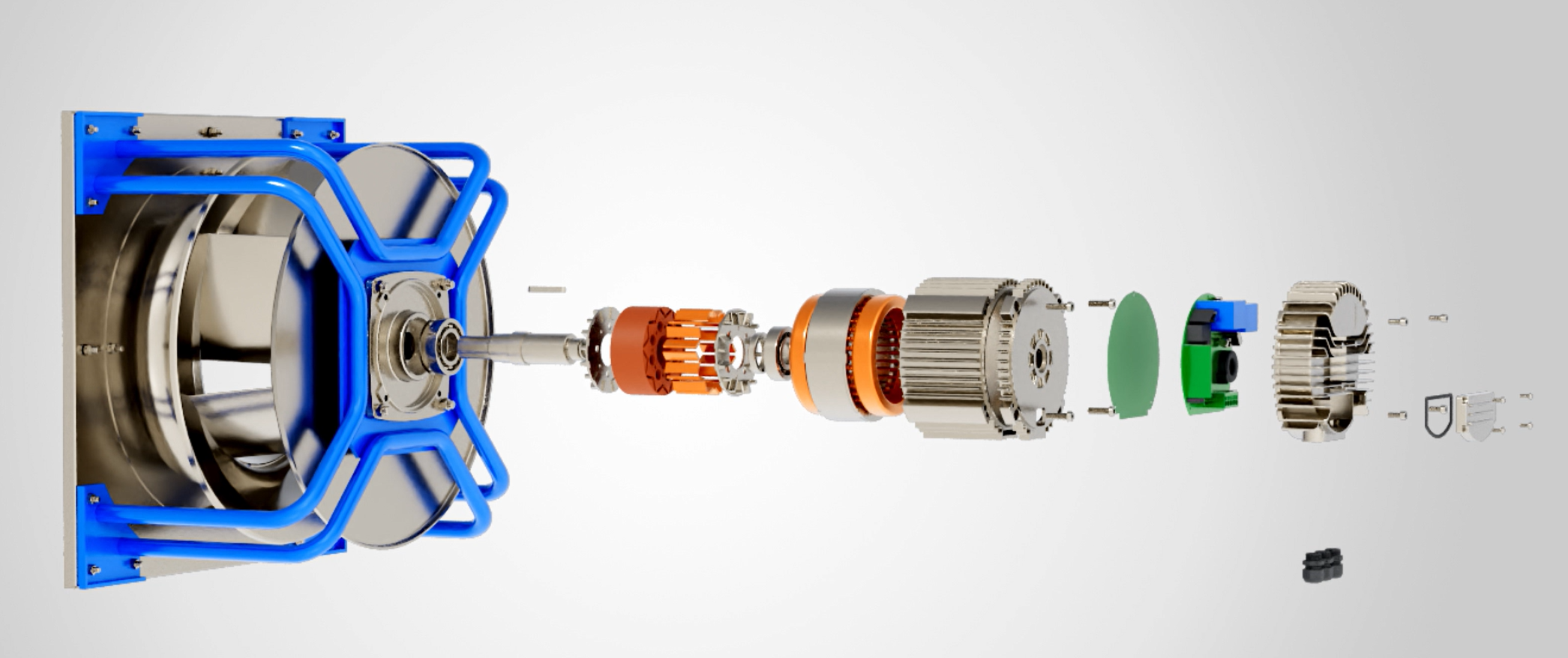

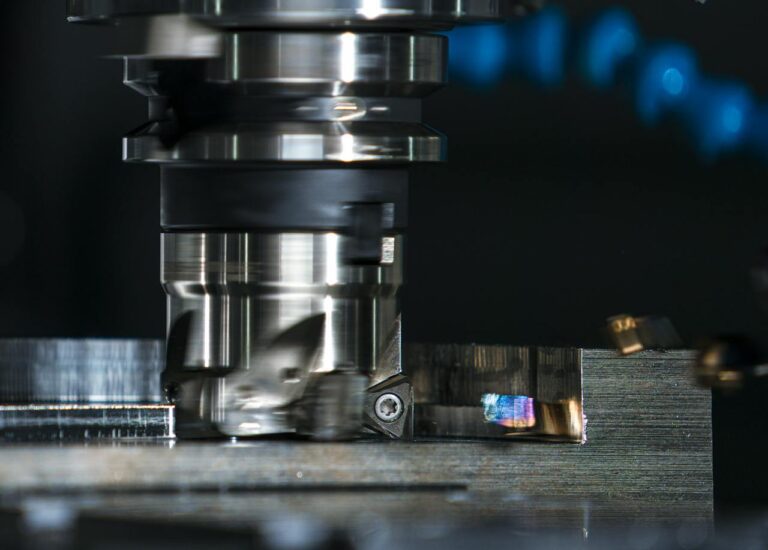

With high quality control standards from Germany, PANKA fan adopts innovative blade design and highest efficiency impeller form to realize the best static pressure output and lowest turbulence disturbance, with higher efficiency, lower noise and longer service life. With the advantages of quick and easy integration and maintenance-free features, the products have passed ISO 9001, CE, AMCA, IE5 certifications, and are applying for more certifications, such as ATEX and TUV, in order to meet the requirements of higher standards.

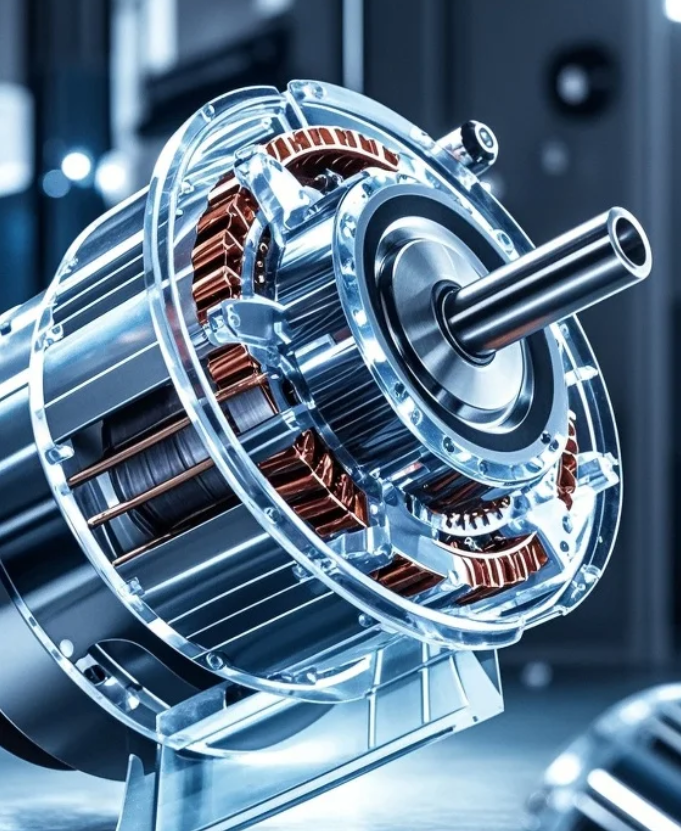

EC fan adopts high-efficiency permanent magnet motor and intelligent control system, with high energy efficiency, low noise, intelligent speed regulation, etc. It is widely used in air-conditioning systems, new energy factories, data centers and other scenarios, which helps customers to realize energy saving and intelligent management.

Multi-purpose plug fans have a flexible design and a wide range of applications to meet the ventilation needs under different working conditions. Its high-efficiency impeller and various material choices ensure stable operation in a variety of complex environments, and it is suitable for commercial buildings, industrial plants, clean rooms and other places.

Axial fans are widely used in industrial heat dissipation, ventilation and air exchange scenarios due to their large air volume and low air pressure. With its compact structure, convenient installation, smooth operation and low noise, it is an ideal ventilation equipment, especially suitable for occasions with limited space.

The air supply and exhaust fan box integrates the functions of air supply and exhaust, with compact design and efficient operation. Its various models and configurations can meet the ventilation needs of different buildings, applicable to commercial buildings, industrial plants, underground parking lots and other places, providing users with flexible and reliable ventilation solutions.

We provide energy-saving solutions for air systems that are customized for different scenarios, optimize airflow organization, accurately match equipment needs, achieve high energy efficiency, and help customers reduce costs and increase efficiency.

In the data center industry, PANKA fans meet the stringent requirements for equipment cooling and air circulation with their efficient thermal performance and low noise characteristics. Our fans are able to operate continuously under high load environments to ensure the stability and reliability of data center equipment.

PANKA fans play an important role in the medical purification industry. We provide fan products that effectively support air purification systems in hospitals and laboratories, safeguarding indoor air quality, preventing the spread of germs and complying with relevant health and safety standards.

PANKA fans play a key role in the precision manufacturing industry, providing accurate air flow control and temperature management. Our products ensure the stability of the production environment, enhancing product quality and productivity.

In the high-speed train industry, PANKA fans are widely used in the ventilation and air-conditioning systems of trains due to their excellent performance and durability. Our fans are able to maintain high performance and low noise at high speeds, providing passengers with a comfortable traveling experience. Meanwhile, PANKA fans are also providing strong support for the cooling of braking system and motor system in high speed trains.

In the HVAC industry, the high energy efficiency and quiet design of PANKA fans make them an ideal choice in the market. We offer products that meet the ventilation needs of a wide range of buildings and facilities to optimize air circulation.

PANKA fans also have a place in the ocean marine industry. Our fans are specially designed to withstand extreme marine environments and high humidity conditions, ensuring air circulation and cooling needs for ships in a variety of situations.

In the new energy industry, PANKA fans provide the necessary ventilation and cooling solutions for battery cooling systems to improve battery performance and life. Our fans are designed to focus on energy saving and efficient operation to meet the industry's need for environmental protection. In addition, PANKA Fans additionally provides DC voltage fans that can be used directly by new energy companies to minimize the loss of power generation to the grid.

In the agricultural machinery industry, PANKA fans help make agricultural equipment more efficient. We specialize in developing fans that operate reliably in a variety of agricultural environments, providing the necessary cooling and ventilation support for farm machinery.

We provide energy-saving solutions for air systems that are customized for different scenarios, optimize airflow organization, accurately match equipment needs, achieve high energy efficiency, and help customers reduce costs and increase efficiency.

Pengke Mechanical & Electrical Equipment (Shanghai) Co., Ltd, a professional fan supplier, provides customers with energy efficient air system solutions with excellent quality and innovative technology. We look forward to working with you to create a better future!

Subscribe to us for the latest news!

© Copyright 2025 - Pangke Mechanical & Electrical Equipment (Shanghai) Co.